Why Does Wall Thickness Matter In 3D Printing?

For a model to 3D print successfully, each part of your model should have the minimum

wall thickness required for the material, printing process and scale of that model.

Certain 3D Printing technologies can make 0.4mm walls for instance. Any thinner walls

in your model will cause the print to fail. If you switch material or sometimes even

another 3D Printer using the same 3D Printing process a 0.4mm wall that used to print

will now fail. If you make a thin figurine measuring 5 CM then a 0.4mm wall could keep

that figurine upright.

Meanwhile if you now want to 3D Print the same model at 30 CM it

might become too fragile or fail. In each of these cases you will want to adjust and

increase the wall thickness. In some other cases you may want to reduce wall thickness

to save on material cost or make an item more elegant. Or you may want to make a clear

material more transparent by reducing the wall thickness. Our intelligent wall

thickness adjustment tools will let you change wall thicknesses at will automatically

to suit different 3D Printing processes or scales.

What is the problem with bad wall thickness?

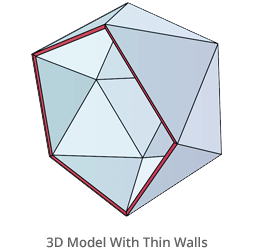

What's cumbersome is that not all 3D models were designed for 3D printing, and could

have areas that are thinner than what your 3D printer and material can actually print.

If you attempt to print a 3D model with thin areas, it could be problematic as it could

lead to unprinted areas of your model or your model falling apart due to gravity or

other forces. This could disfigure your model causing an unsuccessful result with your

print.

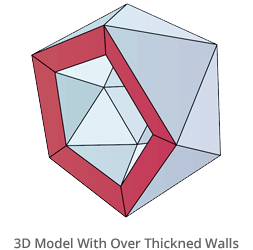

Another problem with thin areas is if you order a print through a print shop or

service bureau, they usually have the tendency to over thicken your model to ensure

print succes.. This is done to reduce their print failure rates and to minimize the

chance of the model breaking while being shipped. This may needlessly increase your

costs or may not be the aesthetic result that you want.

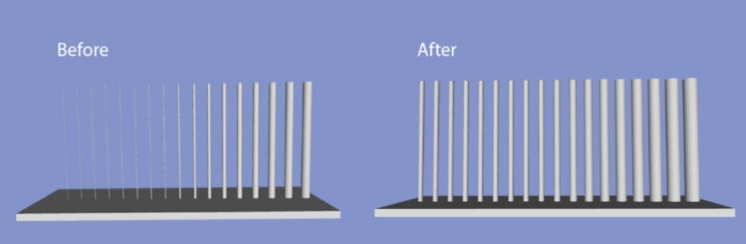

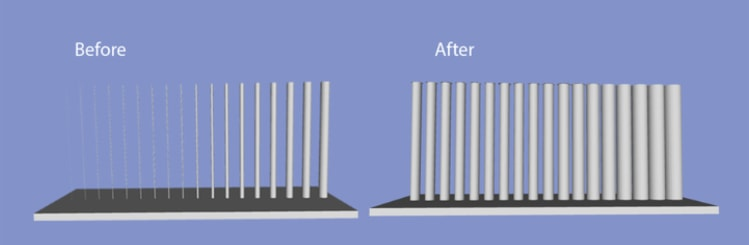

A before and after comparison of a 3D model that has thin areas that need thickening before printing.

3DPrepPro minimum wall thickness adjustment slider

To avoid wall thickness problems with your 3D model. Upload it to 3DPrepPro and let our algorithms automatically thicken your model's walls for printability. Reduce or increase the wall thickness depending on your need automatically.

Get your 3D models analyzed for 3D Printing Sign up now!

Premium feature: Manual wall thickness adjustment slider.

Another problem with thin area is if you order a print through a print or service bureau, they usually have the tendency to over thicken your model to ensure print succes. This is done to reduce their print failure rates and to minimize the chance of the model breaking while being shipped. This may needlessly increase your costs or may not the aesthetic result that you want.

If you don’t have a model that has thin walls and would like to try our 3DPrepPro’s wall thickness feature download the model from here.

What are the most common parts that need thickening?

Wall thickness can apply to areas in models that are very thin. These include hair,

fingers, capes, clothes, nose, ears, weapons, gears, and other thin areas.

Find out how to reduce the number of polygons on your mesh